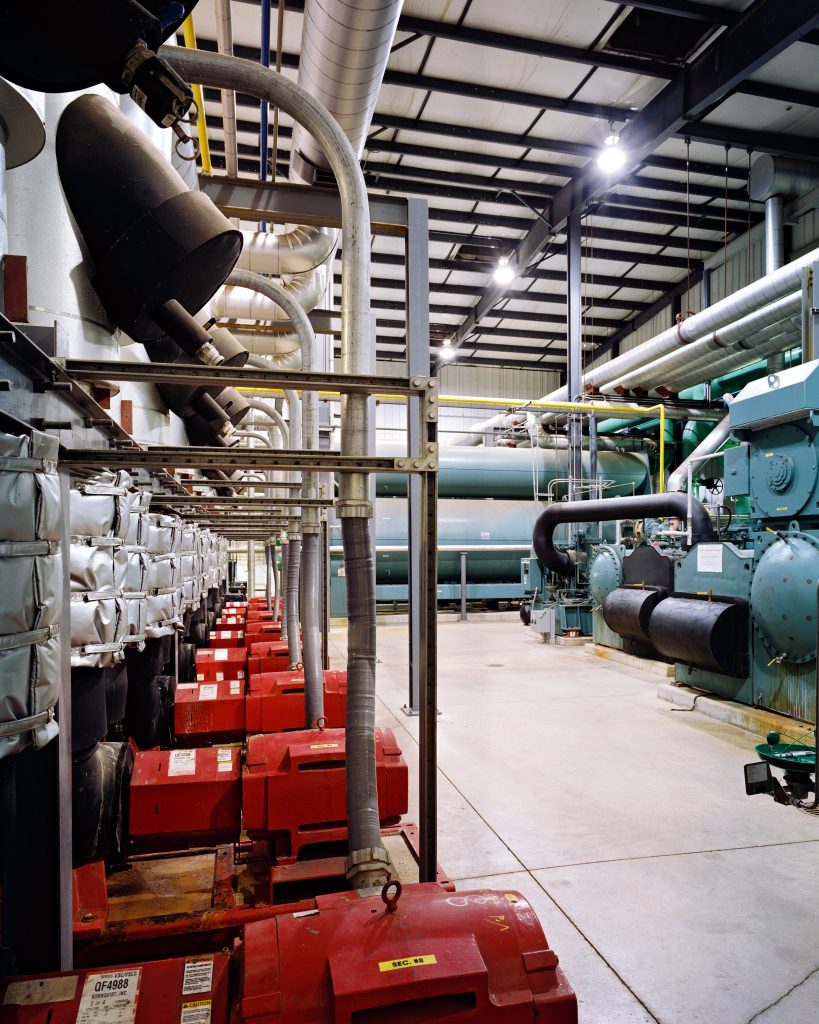

Caterpillar, Inc., Medina Valley Cogeneration Plant

Mossville, Illinois

Combined Cycle Cogeneration Plant includes:

- 47 Megawatt Electrical Generation

- Combustion Turbines, Heat Recovery Steam Generators (HRSG), and Back

Pressure Steam Turbines - 324,000 PPH Superheated Steam at 750°F, 600 PSIG

- 100,000 PPH Back-up Boiler at 250 PSIG Saturated

- Induction and Synchronous Generators

- 13.8 kV, 4.16 KV Volt, 480 Volt, and 120 Volt Plant Electrical Systems

- 138 KV Utility Interconnect

Chilled Water Plant includes:

- 7,200 Tons Refrigeration Capacity

- Electric Centrifugal Chillers and Steam Absorption Chillers

- Natural Gas Engine Driven Centrifugal Chiller

- High Delta-T, Variable-Primary-Flow (VPF) cooling design

- Cooling Tower System

Industrial Technology Group was the Owners’ Engineers and Detail Design

Engineers. We completed:

- Energy Analysis and Financial Payback

- Design from the Conceptual Stages

- Process Design

- Process Flow

- Structural Design

- Detail Design

- Site Survey and Development Plan

- EPA Permitting

Additional ITG Projects

-

Dyno Nobel, Process & Utility Upgrades

Louisiana, Missouri -

Basin Creek Energy, LLC, Basin Creek Generation Plant

Butte, Montana -

Illinois American Water Company, East Plant Renovation

Champaign, Illinois -

Northern Illinois Water Company, SCADA & Control Systems

Champaign, Illinois -

Caterpillar, Inc., Medina Valley Cogeneration Plant

Mossville, Illinois -

GreenHunter Energy, Biodiesel Integration

Houston, Texas